Using machine learning to improve DFM: a case study

By Ruben Ghulghazaryan, Davit Piliposyan, Misak Shoyan

Several years ago, the American University of Armenia (AUA) and Siemens EDA began a collaborative relationship for research and technology development in the semiconductor industry, covering topics such as data compression, mechanical stress modeling and calibration, circuit analysis, and chemical-mechanical polishing (CMP) modeling of integrated circuits (ICs).

ECD modeling

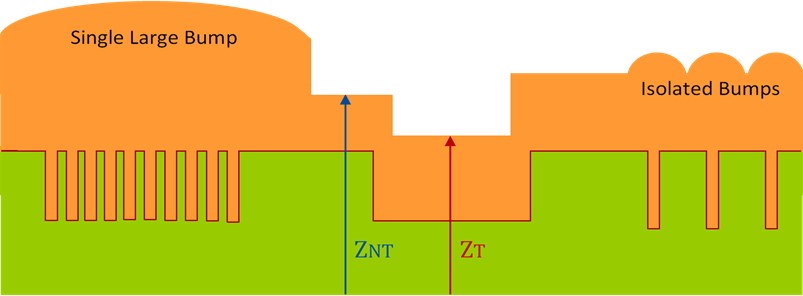

One project investigated the use of advanced machine learning (ML) modeling techniques to predict the complicated topography variations that typically result from the electrochemical deposition (ECD) process. ECD models are used as input in chemical mechanical planarization (CMP) simulations, so the ability to precisely predict the post-ECD surface profile is an essential step to enabling engineers to more accurately predict (and eliminate) potential CMP hotspots before actual manufacturing.

Machine learning

ML is a subset of artificial intelligence (AI) that enables computer systems to recognize patterns using algorithms and data sets, and then use that information to develop solutions. ML algorithms make predictions based on initially gathered (training) data without being explicitly programmed for that task. The project team applied various ML methods to the process used to model post-ECD surface profiles, and evaluated the results to determine which architectures and models provided the best combination of running time and accuracy.

For an in-depth look at the ML techniques they used, and the results of their research, read or download our technical paper, Modeling ECD with machine learning for CMP simulation.

To learn more about the AUA Akian College of Science & Engineering, click here.